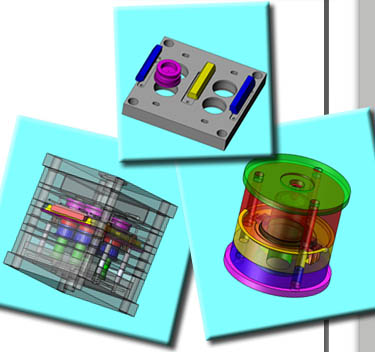

Tool Design

Utilising the CAD model integration into a Die set, expedites layout and design of technical requirements for tooling.

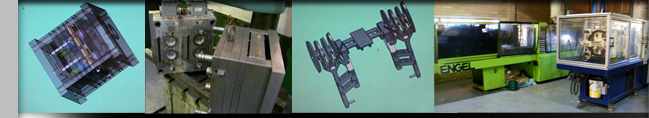

Making the Tool

Through integration with the CAD design of the mould layout, and the direct link to the CNC process, cutting of the mould commences to ensure accuracy in manufacture.

Where required additional processes are employed such as Spark Erosion, Wire cutting and polishing are utilised.

Material.

High Quality Tool steels are utilised in the manufacture of the mould, to meet customer requirements.

Moulds are tested in house and components approved prior to hardening, utilising Plasma Nitriding or Vacuum through Hardening, dependent upon customer and mould requirements.